Home » Environmental Solutions » Incomat CCGM

Filtration, separation, protection, containment, reinforcement and lining: These, together with erosion control, are among the key functions of geosynthetics in hydraulic engineering. Our partner, HUESKER has a 150-year-plus track record in textile production, now ranked among the world’s market leaders in the geotextile sector.

Incomat is the product of choice for erosion control or lining solutions that require a constant thickness-concrete cross-section or impermeable concrete mattress. The unique manufacturing method, involving the incorporation of vertical ties, gives the geotextile encasement a dimensional stability that is unmatched worldwide.

This dimensional stability guarantees a constant concrete cross-section even under difficult installation conditions, e.g. with uneven bases or underwater applications. The adaptability of the concrete mattress system gives it a clear edge over all conventional concrete solutions. Through custom-fabrication, the mattresses can also be made to accommodate penetrations and custom, complex geometries as per the requirement.Incomat acts in conjunction with the concrete to create a highly efficient, permeable revetment suitable for strong bases and hydraulic loads.

Benefits

Quick and easy to install.

Instant curing.

Water efficient.

No effect of UV rays.

Constant thickness, also in uneven bases.

Low Hydraulic roughness

Project specific customisation.

Combined lining and erosion control.

Available in permeable or non-permeable forms.

Long life, used in over 100 countries for more than 50 years.

Available from 100 mm to 300 mm thickness to suit every application.

Applications

- Bed Protection

- Slope Protection

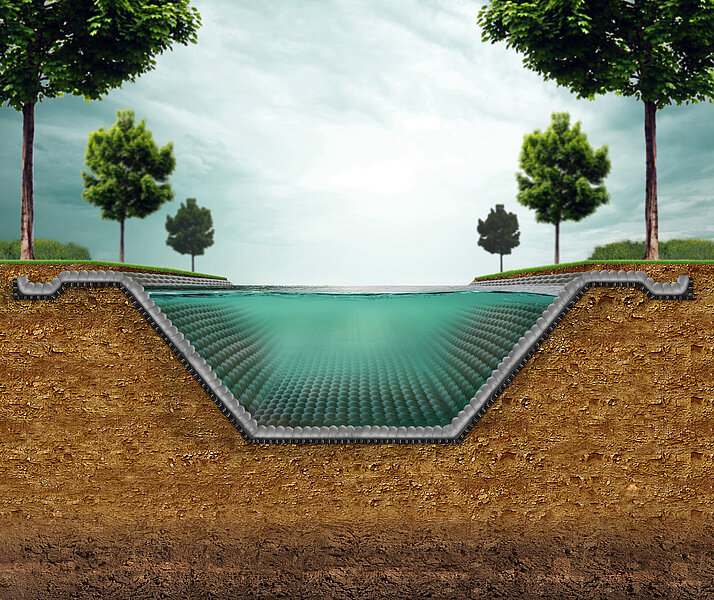

- Stormwater Holding And Storage Basins

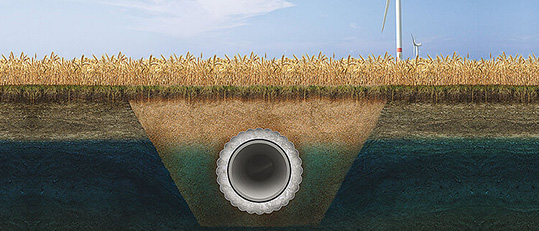

- Incomat Pipe Protection System

- Bund Lining

- Ditch Lining

- Coastal Protection

- Erosion Control

- Waterbody Protection

- Culvert Repairing

- Reinforcing Existing Structures

How It Works

Incomat Concrete Mattress

The Incomat geotextile concrete mattress has been used successfully in hydraulic engineering applications for erosion control or as a cover lining since the early 1960s. Incomat mattresses comprise two high-tensile synthetic woven layers connected by a regular arrangement of ties. The void between the two woven layers is filled in-situ with fluid concrete. Various models are available for the installation of permeable or impermeable concrete revetments with a customised mattress thickness.

Continuous refinements have seen a steady expansion of HUESKER‘s product portfolio and the associated range of applications. Uses of Incomat include slope protection, bed, bank and coastal protection, canal linings and pipeline covers.

System Features

- Globally unique manufacturing method with incorporation of vertical ties.

- Very high dimensional stability when filled.

- Efficient concreting cycles with minimum downtime.

- Extremely high adaptability to existing base.

- Production of panels up to 1,000 sqm possible.

- No formwork required.

- Connection by means of factory-fitted industrial zips.

- Range of mattress thicknesses.

- Custom-design to suit any geometry.

- Underwater installation possible.

Simple Installation Principle

Preparation of formation

Spreading out of panels

Filling of panels with fluid concrete/mortar

Signet offers a broad range of premium-quality geosynthetic products for hydraulic engineering. These include containment systems such as tubes, containers or sandbags, sinking mattresses, filter non-wovens, sand mats, clay liners and dam base reinforcement. For more information, please visit our partner’s site: https://www.huesker.co.uk.