Rubber Dams

Home » Environmental Solutions » Rubber Dams

What are Rubber Dams?

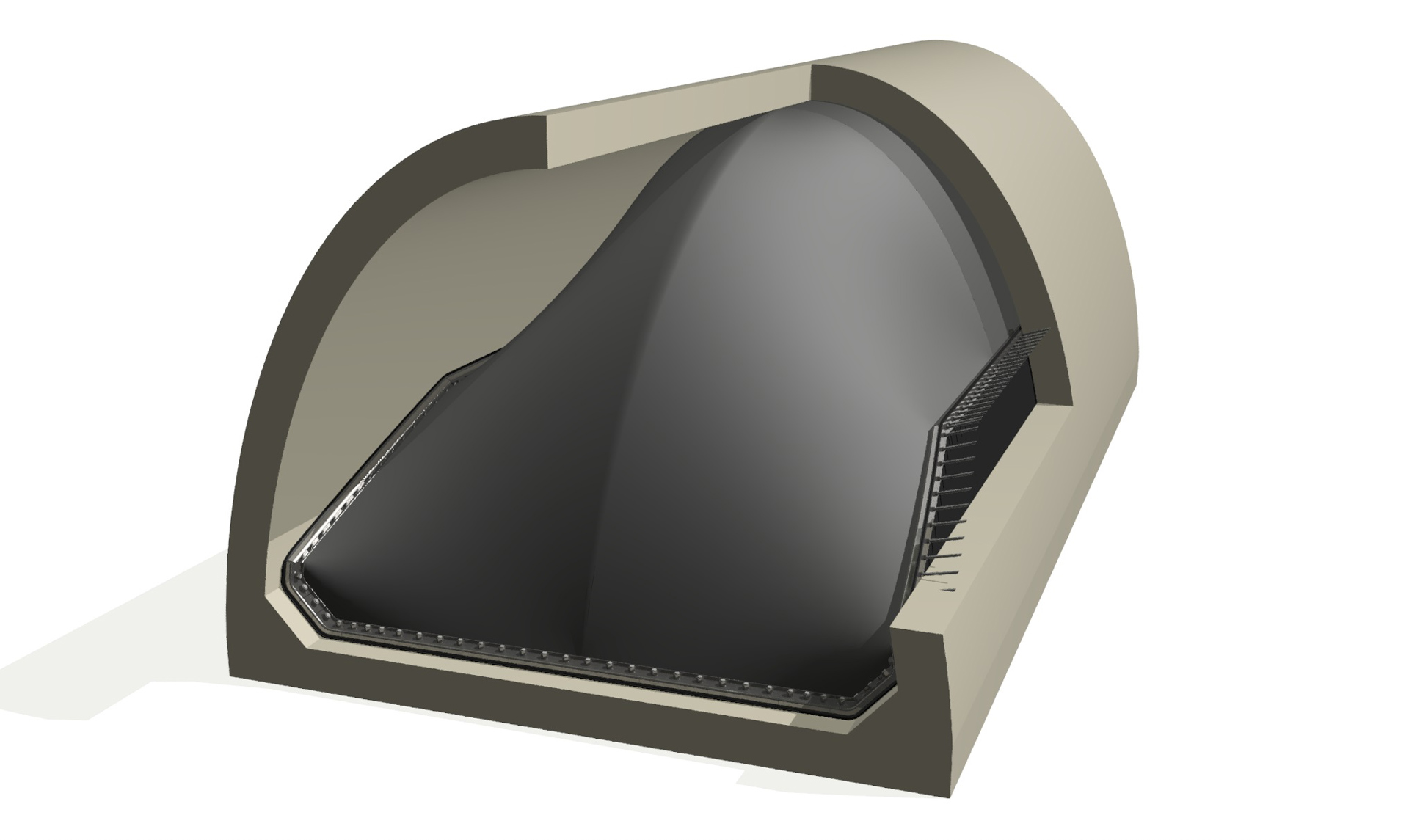

Rubber dams are hydrostatic structures provided with a bladder of textile-reinforced rubber. It is screwed to the dam structure which creates a tight inner space. The dam may be water-filled or air-filled.

Purpose of a rubber dam

It creates a balance between the internal pressure of the dam and the water load on the bladder.

How does it work?

It works in the following order

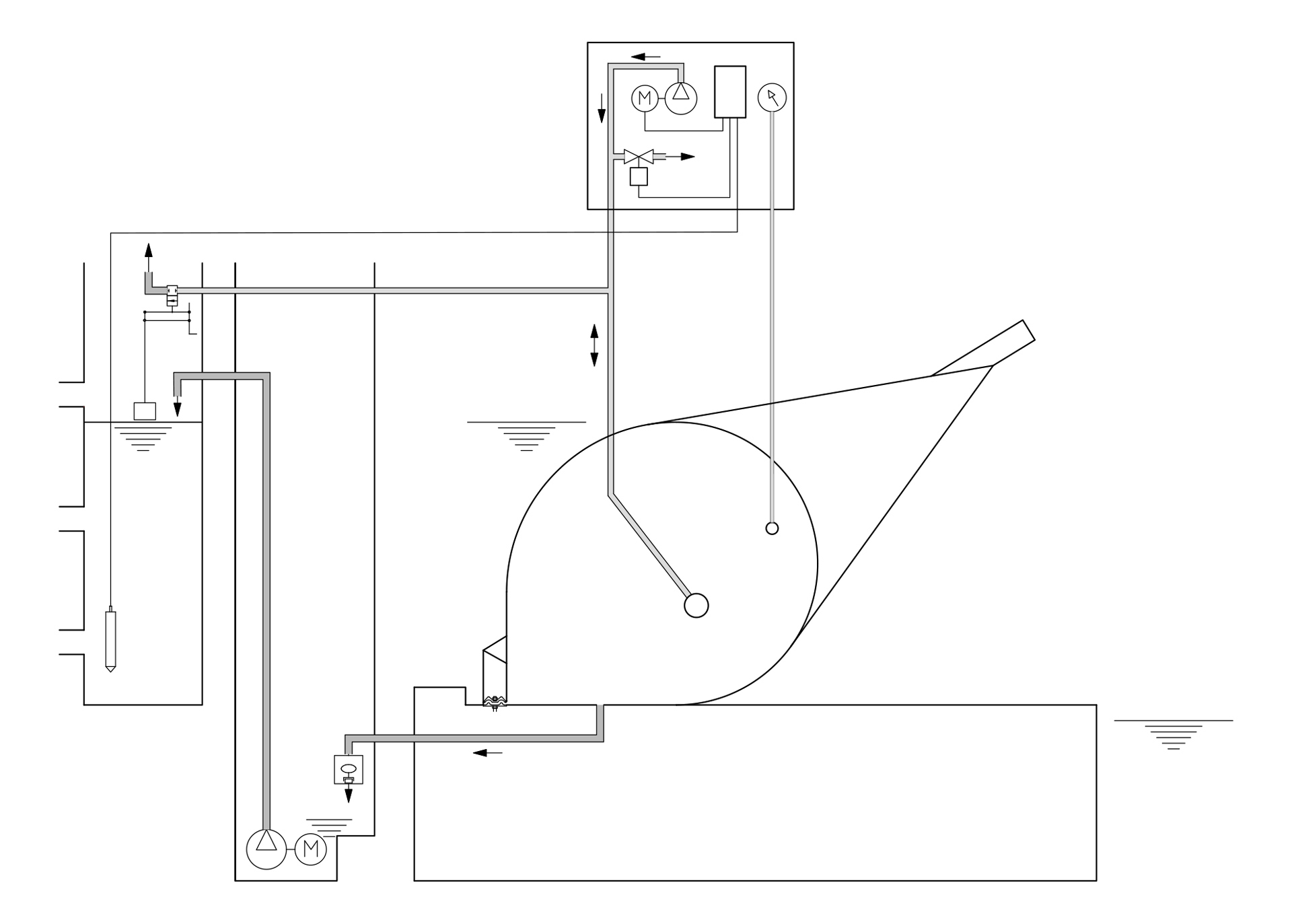

- The pumps and valves are controlled from a power house.

- The appliances required for water-filled systems are located in underground shafts and for air-filled systems in an over ground power house.

- By varying the filling volume and adjusting the height of the bladder, the retention and discharge sections are adjusted as per requirements.

- Using the respective control system, the retention set point is set and adhered to reliably.

- The duration of Inflating and/or deflating is also adjusted as per requirements.

- The filling medium is supplied to the rubber dam by pipes connected with the control system.

- As soon as the rising water level in the retention zone exceeds the retention set point, the bladder is gradually deflated until complete depletion, thus clearing the full dam opening.

- As the water level decreases the bladder is inflated.

In this way the upstream water level is kept constant at the specified retention set point.

The choice of the appropriate filling medium depends on the requirements of the individual project. A number of criteria have to be considered at the planning stage.

Air-filled Rubber Dams

What is air filled rubber dam?

The bladder of this type of rubber dam is filled with air. The dam is kept erect only by the air pressure inside the bladder.

How does it work?

For inflating the dam, the compressor located in the power house on the riverside feeds air into the bladder through a control pipe. The inflating bladder is completely air-tight, including the side wall sections, impounding the upstream water as the filling proceeds.

The deflation process is carried out by electrically or pneumatically controlled valves. Additionally, all valves can be operated manually. In the case of small dams, the entire control system may be housed in a thermally insulated and heated control cabinet.

Unique product features

- The rubber dam is equipped with a number of sensors ensuring safe operation, precise setting and permanent monitoring of the dam operation. The sensors measure the water level in the retention area and the internal pressure of the bladder.

- The interior of the bladder is monitored for possible condensate formation or intrusion of outside water.

- Separate measuring pipes are provided leading to the control house to maintain the internal pressure of the bladder for each span.

- The control system developed by Floecksmühle ensures strict observance of the retention set point.

- These are not overtopped as evenly as water-filled dams. Up to a deflation of approx. 95% to 90% of the maximum bladder height, air-filled dams behave in a way similar to water-filled dams. When depleted further, a V-shaped dent forms involving higher overtopping of the dam.

Where can it be used?

Rubber dams may be used in locations where the downstream water is retained. When there is no downstream retention, the air-filled bladder is fixed to the dam body with one upstream fixing line. If the retained downstream water reaches up to the non-overtopped dam, a second fixing line may be necessary.

Water-filled Rubber Dams

What is a water filled rubber dam?

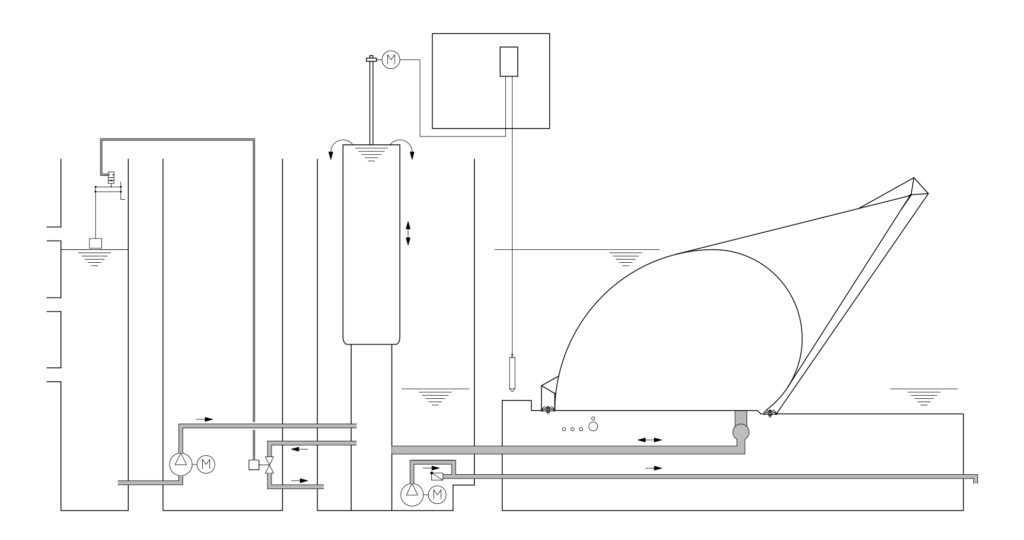

In water-filled rubber dams water pressure is created in the bladder is created to the principle of communicating vessels as a water column in a regulating shaft connected with the inside of the bladder by a pipeline (inlet/outlet pipe). The height of the water column in the regulating shaft determines the internal pressure and thus the height of the inflated bladder.

How does it work?

The water bag – and thus also the bladder – are filled by one or more filling pump(s). The water is taken from the supply shaft which is generally connected with the upstream water by one or more pipes.

The bladder is inflated by feeding water into the regulating shaft.

As soon as the pressure inside the bladder exceeds the sum of external forces (bladder weight and water load), the bladder starts to prop up. The inflated bladder retains the water in the retention area.

Unique product features

- The crest of water-filled rubber dams is always horizontal, even when filled only in part. Therefore the overtopping water flows very evenly across the dam.

- It can measure parameters like the water level in the retention area and on the downstream side.

- It can also measure the bladder height if required.

- As a consequence, water-filled dams make it possible to calculate the discharge rate in a certain range. In this way the discharge rate may be accounted for in the control system as a control parameter.

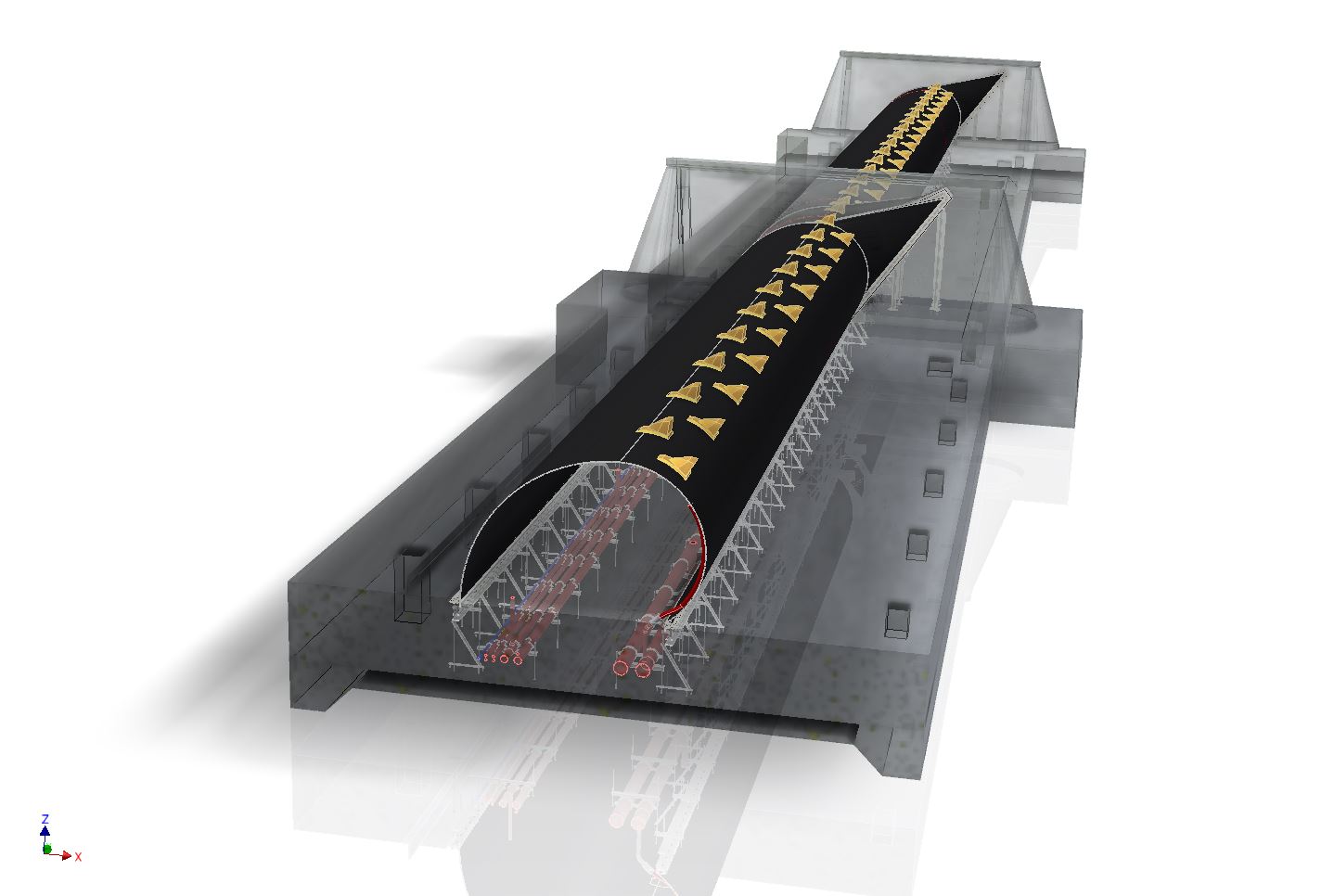

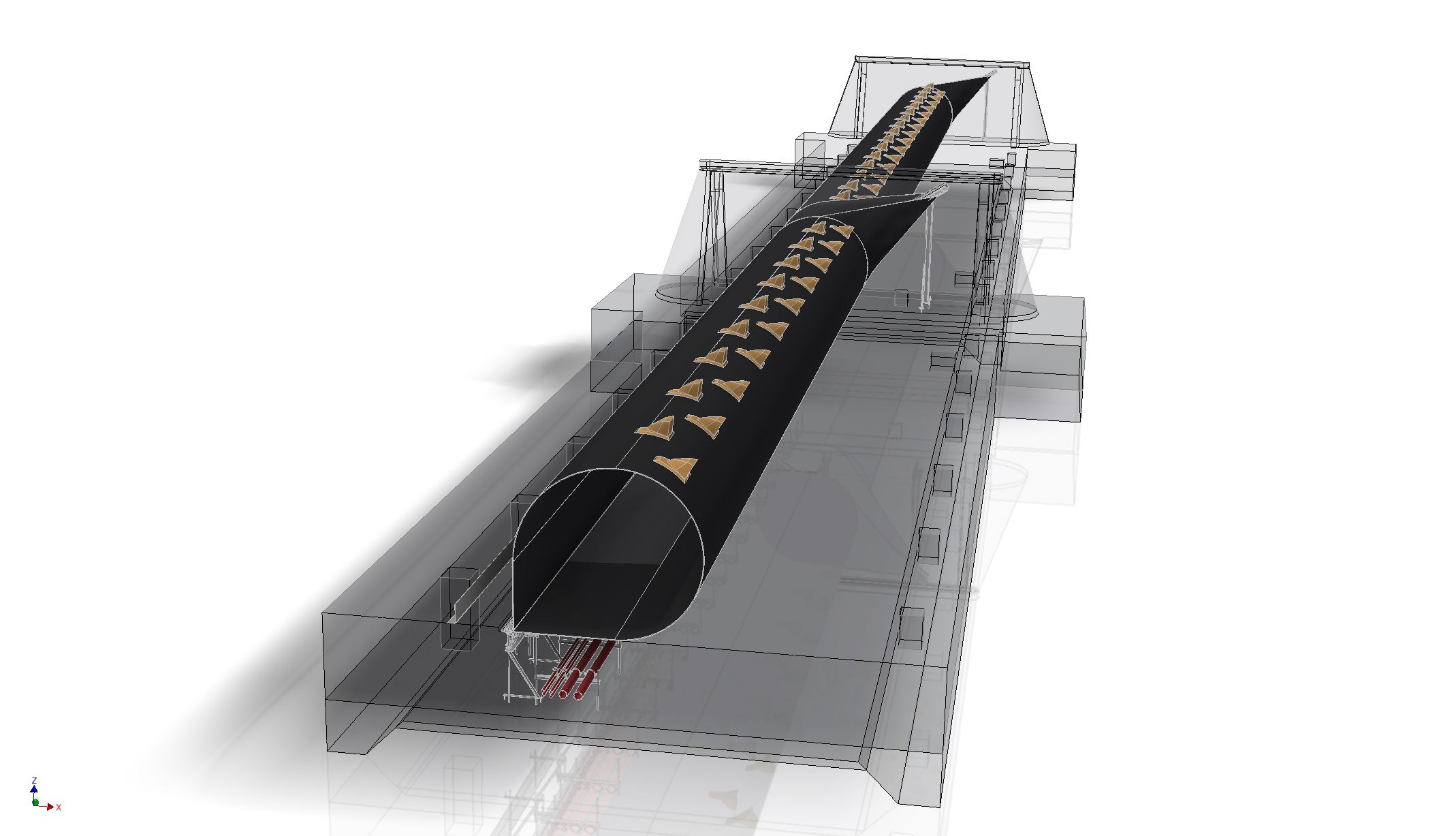

Inflatable gates in sewage water systems

What is an inflatable gate?

An inflatable gate is installed in a sewage water system to allow the use of the existing sewage duct as an intermediate reservoir. They are generally designed as air filled rubber gates. Depending on the design, the complete cross section of the sewage duct can be closed.

Inflatable sewer gates are installed in sewage ducts of combined sewage systems.

How does it work?

In combined sewage systems, rain water and wastewater are channeled together to the water treatment plant. As the collector duct and the water treatment plant are designed for a limited capacity, part of the sewage water from heavy rains must be stored temporarily to ensure that the water treatment plant’s capacity is not exceeded.

With an inflatable gate the discharge volume can be regulated in such way that the capacity of the connected sewage treatment plants is not exceeded.

Inflatable sewer gates offer several advantages:

- They can easily be installed in existing sewage water systems.

- The simple design of inflatable gates requires low maintenance.

- Electro-mechanical components can be installed in easily accessible operating

shafts. - Existing sewage ducts can be used as buffer reservoirs for sewage water.

For more information, please visit our principal site: http://www.floecksmuehle.de/